The Skills Required

Fen's extensive knowledge of sensor technology and processor sub-systems afforded us the ability to select the optimum combination of components from a size, power and function perspective.

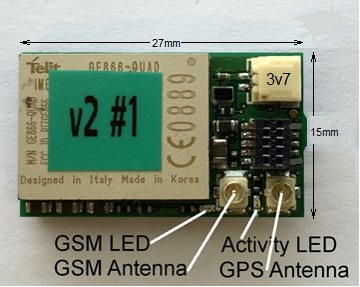

A deep understanding of the PCB layout process and its limitations allowed us to compress the solution into the smallest physical footprint possible whilst still meeting production and conformance criteria.

Fen has an intimate knowledge of coding for a wide range of processors and a deep understanding from driver level up to embedded applications. This ensured Fen extracted the maximum performance using minimum power from the devices selected.

Domain experience allowed Fen to deploy several tricks to achieve market leading performance of the product.

Experience of an integrated approach to hardware and software design enabled Fen to architect a system solution that from a function and power perspective was greater than the sum of its parts.

The Brief

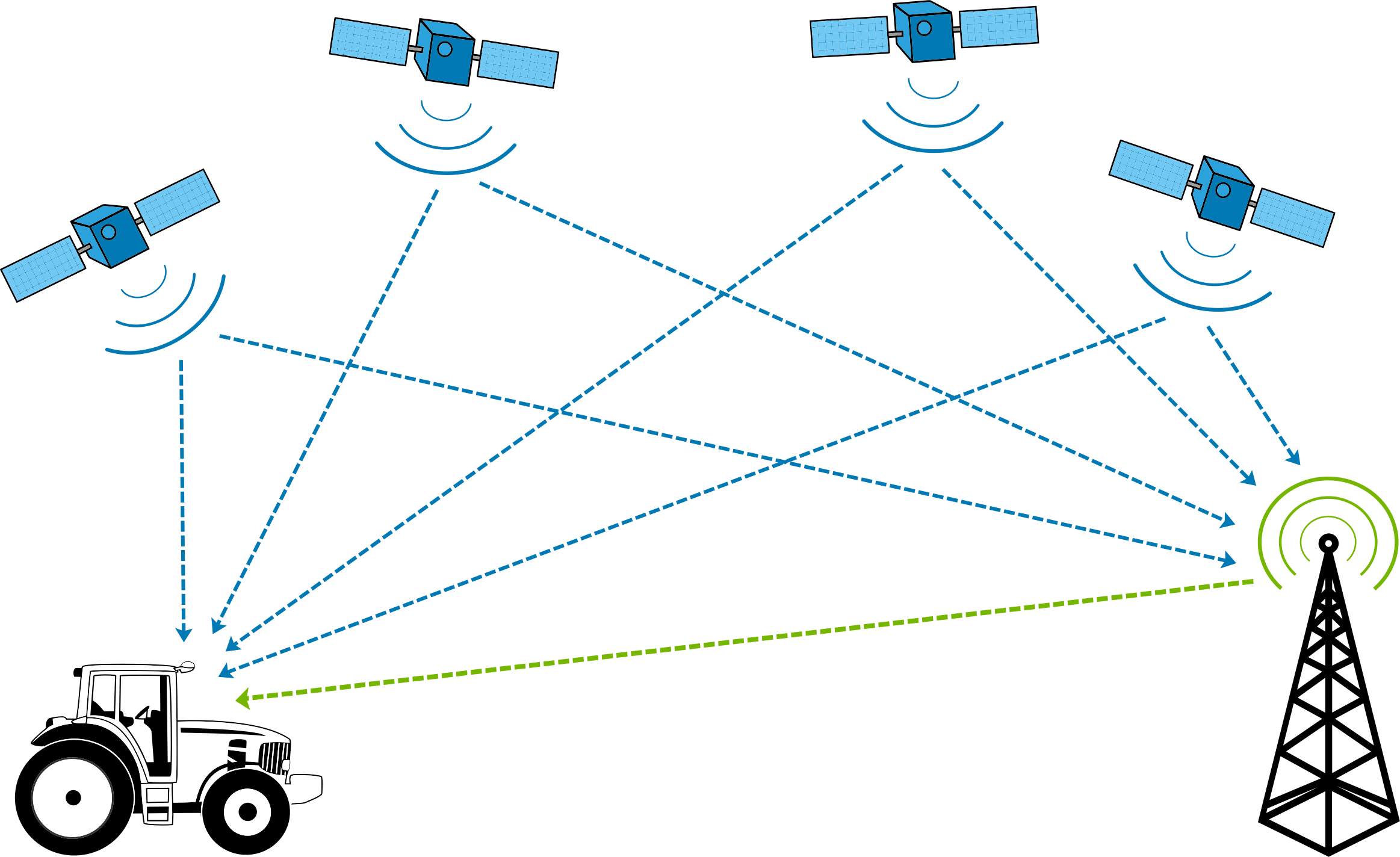

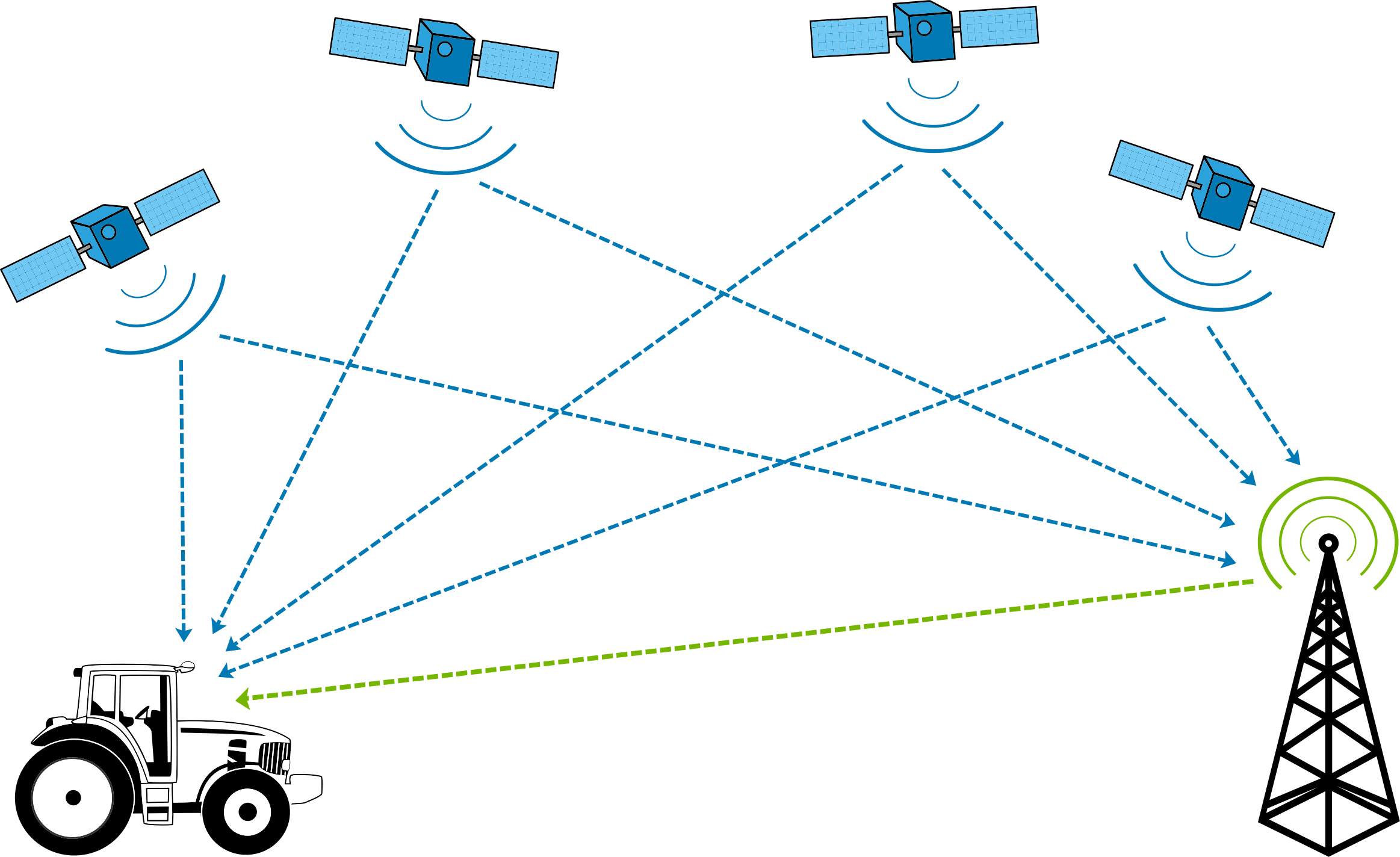

The client wanted an undetectable, ultra-low-power location device to be used to discreetly track high value items in a number of different usage scenarios. As well as the tracking function, the device needed to have the ability to be integrated with other sensors and functions.

The real challenge was to accommodate the full range of scenarios: months of lying dormant followed by a period of intense activity, then an extended period of location reporting at regular intervals.

A further challenging requirement was remote, in the field, device re-configuration, without compromising the strict power usage requirements.

The Solution

Fen initially created a usage model to analyse key power consuming functions and show using different behavioural models how the devices could be optimised for minimum power consumption across the board. Further investigations then matched optimal technologies and devices to the primary product functions.

Meeting the extremely lower power usage expectations could not simply be achieved by component selection alone. An integrated approach to matching a suite of key components was a first step. Lower level embedded software was then used to access the individual components’ low power modes, causing them to work together in a power efficient manner. Further to this, application layer embedded code was used to intelligently configure a number of different high level usage profiles.

Only through this multi-layer cross-system approach could Fen achieve the exacting product level power requirements.

A clever live remote configuration scheme was devised to enable the system administrator to manage and re-purpose devices in the field for further power optimisation and functional re-profiling, with no significant detriment to the battery charge life.

The Skills Required

Fen's extensive knowledge of sensor technology and processor sub-systems afforded us the ability to select the optimum combination of components from a size, power and function perspective.

A deep understanding of the PCB layout process and its limitations allowed us to compress the solution into the smallest physical footprint possible whilst still meeting production and conformance criteria.

Fen has an intimate knowledge of coding for a wide range of processors and a deep understanding from driver level up to embedded applications. This ensured Fen extracted the maximum performance using minimum power from the devices selected.

Domain experience allowed Fen to deploy several tricks to achieve market leading performance of the product.

Experience of an integrated approach to hardware and software design enabled Fen to architect a system solution that from a function and power perspective was greater than the sum of its parts.